polymer coatings

what is polymer coating?

The coating of any material with a polymer describes the surface treatment process of polymer coating. Due to the wide range of process variants, we can meet different requirements for components.

what type of surface coating is suitable for my application?

It is not always easy to find a straightforward answer to this question, especially when it comes to the wide range of possible polymer coating processes. However, the number of possible coating options can be narrowed down quite well by our experienced experts. Before we make a final decision, we often test different solutions by means of sample coating processes.

If you would like guidance on the best surface coating solution for your application, please contact us.

everyday polymer surface coatings: PTFE coatings

PTFE in PTFE coatings stands for polytetrafluoroethylene, a semi-crystalline polymer consisting of fluorine and carbon. When heated, the consistency of PTFE becomes soft and rubbery, but usually not meltable or liquid. PTFE has anti-adhesive properties and can hardly be wetted. It can be subjected to a wide range of temperatures (continuous service temperatures: from approx. -200 °C to 250 °C; temporary exposure: up to 300 °C; crystallite melting point: 327 °C); PTFE is almost incombustible. All of these properties make PTFE polymer coatings ideal for the coating of frying pans, for example. Thus, PTFE coating processes are part of our everyday life.

high-quality polymer and fluoropolymer coatings for almost all base materials

Our robust and partially patented premium polymer surface coatings are applied onto the workpieces using special coating methods. Our special technique ensures long-lasting coatings which become extremely well anchored in a wide variety of base materials:

- Steel

- Stainless steel

- Ceramics

- Plastics

- Copper

- Aluminum

As an industry leading polymer and fluoropolymer coating manufacturer, we can offer products for a wide array of applications. Our customers from the chemical industry order this type of protective coating for containers, pipelines, valves or sensitive probes. Anti-friction and non-stick coatings prevent the formation of deposits, an indispensable feature in this area.

In electrical engineering applications, the thickness of polymer coatings determines the degree of insulation of battery connectors or bus bars. When it comes to electroplating, the electrical insulation and non-stick properties have proven to be ideal for bathroom radiators, racks and wash baskets. Surface coatings in medical industries on medical instruments, such as tweezers, grips for pliers or electrode spoons, have insulating and dirt-repellent effects and are able to withstand sterilization temperatures.

In the heart of the southern Netherlands, a technologically advanced manufacturer is redefining boundaries with cutting-edge solutions for the Industry, Mobility, and Semiconductor sectors. Specializing in mission-critical components, the company seamlessly combines innovation and precision to meet the highest standards.

To protect sensitive electronic components and reduce noise, parts are cast under vacuum in custom-engineered moulds. These vacuum-moulded components are formed using specialized moulds that are coated with a premium polymer coating by Aalberts surface technologies.

This high-performance coating plays a vital role: it ensures a smooth surface finish, enables easy release of the moulds, and significantly simplifies mould cleaning. Thanks to its excellent temperature resistance and outstanding chemical durability, the coating withstands the demanding materials used in production—ensuring consistent quality and operational efficiency.

polymer coatings have many significant advantages

Even extremely adhesive materials will not adhere to polymer coatings. The result: significantly reduced cleaning efforts and a lower consumption of cleaning and release agents. Thus, it is possible to effectively shorten and reduce machine downtimes caused by maintenance work or soiling. Since PTFE or PFA coatings enhance the surface quality of your components, this effect will be further intensified.

With a roughness of partially below 1.0 µm and a virtually pore-free surface, our high-performance polymer coatings get their job done with minimum sliding friction. Our experienced specialists will define the values for your individual application. To ensure excellent protection against wear, we apply additional reinforcement layers.

Fluoropolymer coatings offer first-class protection against atmospheric corrosion, contact corrosion and condensation corrosion. Depending on the specific coating material and individual conditions, the thickness of the protective coatings may vary between 5 and 1500 µm.

Viscoelastic polymers are characterized by excellent resistance to halogens and solvents as well as by high resistance to acids/alkalis (up to pH 12). They do not have any difficulty whatsoever in withstanding temperatures between -40 °C and +290 °C.

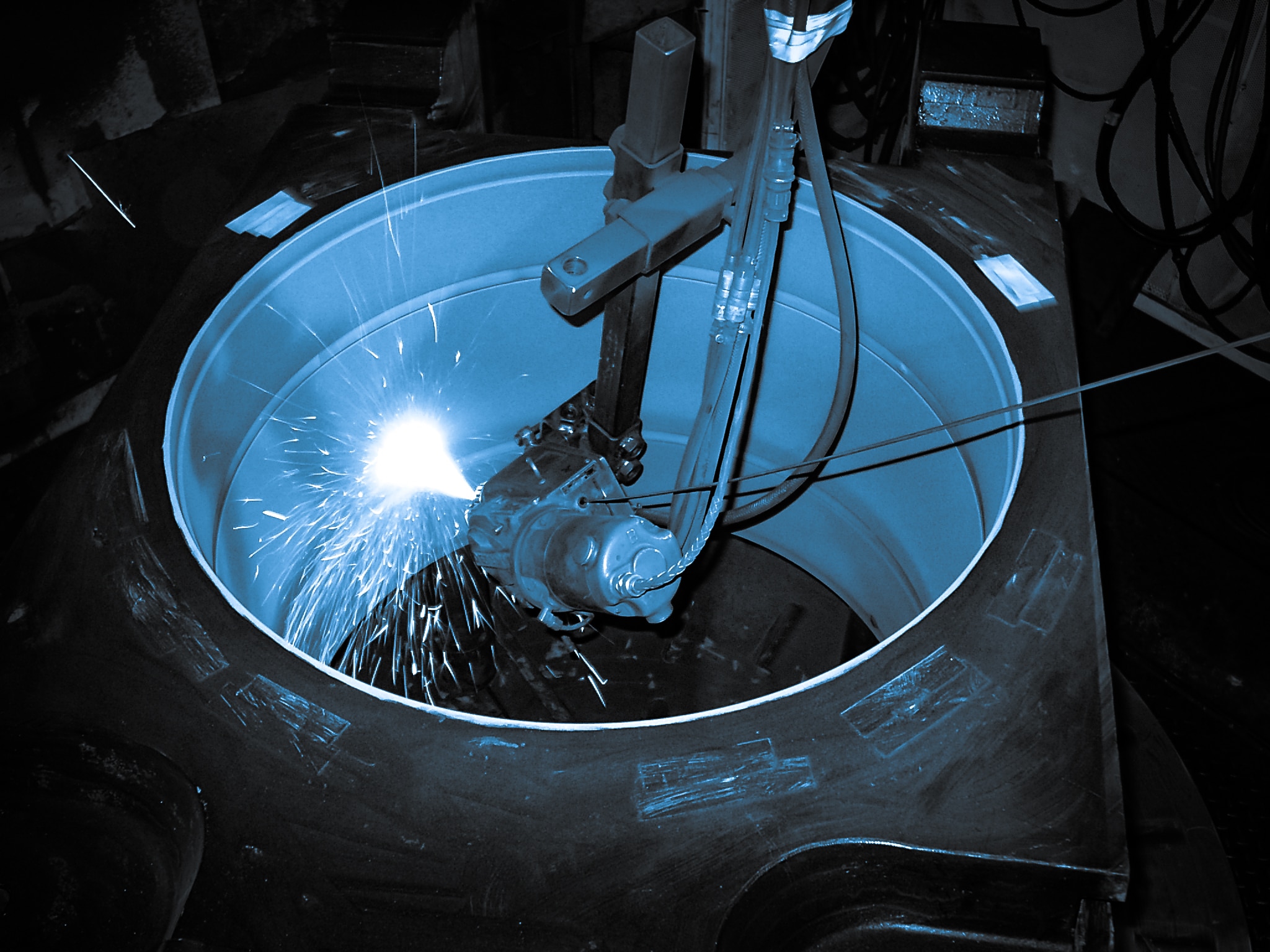

PTFE coatings: no adhesions during work with rubber

Teflon® coatings stand out with their excellent non-stick properties: Even tricky ingredients, such as adhesive or rubber, will not adhere to the hydrophobic surface finish. Teflon® was originally developed for cookware. Today, we use the 5 to 50 µm thick synthetic surface coating in single-, double- and three-layer systems, which allows us to cover a broad range of possibilities. PTFE coatings can be applied to workpieces in dimensions of up to 10 x 3 x 3 meters.

overview MagnaCoat® and TempCoat®

Process | How it works | Characteristics | Base materials |

MagnaCoat® | Electrostatic application followed by thermal melting | – corrosion protection – good non-stick properties – high dielectric strength – excellent barrier properties for chemical resistance | – aluminum – steel – stainless steel – other alloys |

TempCoat® | Created in special polymer and fluoropolymer coating procedures | – high chemical resistance – excellent non-stick properties – excellent gliding properties | – aluminum – steel – stainless steel – copper – ceramics – plastics |

MagnaCoat® polymer and fluoropolymer coating

MagnaCoat® coatings are thick-film polymer and fluoropolymer coatings with a virtually pore-free surface.

MagnaCoat® coatings are thick-film polymer and fluoropolymer coatings with a virtually pore-free surface. MagnaCoat® can be applied electrostatically and is thermally melted. The coating thickness is 0.3 to 0.5 mm, depending on the heat capacity of the parts to be coated. The mechanical strength of the coating permits subsequent machining, e.g. by grinding. In this way, precise dimensional tolerances can also be achieved.

MagnaCoat® is a high-quality, thermoplastic fluoropolymer characterized by good thermal, chemical and dielectric properties.

MagnaCoat® coatings offer outstanding

- Corrosion protection

- Good non-stick properties

- High dielectric strength, even at higher temperatures.

- Excellent barrier properties in terms of chemical resistance

The MagnaCoat® process creates virtually pore-free, non-diffusing thick-film coatings. The combination of these brilliant properties makes MagnaCoat® the ideal solution for applications subject to chemically aggressive conditions.

The following materials are suitable for a MagnaCoat® plastic coating:

- Aluminum

- Steel

- Stainless steel

- Other alloys

fields of application of MagnaCoat®

MagnaCoat® is suitable for heavy-duty corrosion protection. As an innovative polymer and fluoropolymer coating manufacturer, we have been developing this polymer coating for applications which require not only chemical resistance but also non-stick properties. Besides, this type of coating can be used where the diffusion resistance of comparable coatings is not sufficient. The temperature resistance exceeds the values of the systems which are usually used in this area.

Typical applications in the chemical industry include:

- Storage containers

- Reaction vessels

- Valves

- Agitators

- Sensors

- Rotary dryers or calendar rolls

TempCoat® polymer coating

TempCoat® coatings are created in special polymer and fluoropolymer coating procedures.

During the TempCoat® process, special polymer and fluoropolymer coatings are created. Due to the targeted modification of the surface structure with defined roughness profiles, the contact surface is reduced, which results in enhanced non-stick properties. Thanks to their low static and kinetic coefficients of friction, fluorinated polymer films are an indispensable coating material for a wide range of industrial applications. The slight difference between both values reduces slip-stick phenomena, which is a huge advantage when it comes to alternate movements.

TempCoat® is a fluoropolymer coating and offers:

- High chemical resistance

- Excellent non-stick

- Gliding properties

Multi-layer reinforcement coatings or the use of special additives, such as graphite or molybdenum disulphide, make it possible to tailor the coatings to your individual application. Thus, it is possible to improve demolding processes by multi-layer, wear-resistant non-stick systems or to use the coating’s outstanding dry lubrication properties to protect sliding components against malfunction.

TempCoat® coatings are applied to the following materials:

- Aluminum

- Steel

- stainless steel

- Copper

- Ceramics

- Plastics

fields of application of TempCoat®

TempCoat® polymer coatings come into play in technical areas whenever high wear resistance and good gliding and non-stick properties are required. The efficient and trouble-free processing and transportation of metals, plastics and paper in different production processes are no longer possible without excellent anti-friction properties of surfaces which come into contact with products. Sliding bearings modified with TempCoat® are indispensable in many applications and sectors, such as the printing, bakery and chemical industries.

downloads

frequently asked questions

WHAT ARE THE ADVANTAGES OF MAGNACOAT® COATINGS FOR THE CHEMICAL INDUSTRY?

MagnaCoat® fluoropolymer coatings are resistant to a wide range of chemicals, even at higher process temperatures. Metallic materials are thus better protected against attacks from acids and alkalis.

WHICH BASE MATERIALS CAN BE COATED WITH TEMPCOAT®?

Base materials whose temperature resistance exceeds 250 °C, such as metals, ceramics and plastics, are suitable materials. In exceptional cases, it is possible to use air drying materials. Temperature-sensitive materials will then cure at ambient temperature.

WHY ARE PTFE COATINGS PARTICULARLY SUITABLE FOR THE COATING OF FRYING PANS?

Out of all the polymer coatings available, PTFE coatings have the highest continuous service temperature. Usually, these coating systems are further reinforced by additives, which results in increased abrasion resistance, which in turn increases the product’s service life.

WHICH POLYMER OF FLUOROPOLYMER COATING IS SUITABLE FOR WHICH APPLICATION?

Sometimes, the first approach does not give a clear answer, especially when it comes to the wide range of possible polymer coating processes. Although our experienced experts are quite good at narrowing down the number of possible coating options, sample coating processes with several coating varieties are often inevitable and an important part of the polymer coating manufacturing process.

process locations

Any questions? Contact us directly or select a process location near you.

Beuningen

the Netherlands 51.85577565.735604 beuningen@aalberts-st.com +31 24 677 7911 show locationCleveland (Tennessee)

United States 35.1227709-84.9104398 info@aalberts-st.us +1 423 559 9900 show locationFairburn (Georgia)

United States 33.5542357-84.5850179 info@aalberts-st.us +1 770-969-9191 show locationKirkby-In-Ashfield

United Kingdom 53.1043759-1.2474762 nottingham@aalberts-st.com +44 1623 753 107 show locationLandsberg am Lech

Germany 48.068575810.8542243 landsberg@aalberts-st.com +49 8191 91186 10 show locationLüneburg

Germany 53.245976910.4758467 lueneburg@aalberts-st.com +49 4131 882 10 show locationMilwaukee (Wisconsin)

United States 43.1692314-88.019432 info@aalberts-st.us +1 414 357 0260 show locationNidda

Germany 50.42982898.9779735 nidda@aalberts-st.com +49 6043 9613 0 show locationPulversheim

France 47.8338557.301753 pulversheim@aalberts-st.com +33 389 2832 80 show locationTatabánya

Hungary 47.582185518.3456132 tatabanya@aalberts-st.com +36 34 5146 70 show locationLöddeköpinge

Sweden 55.773253712.9985087 loddekopinge@aalberts-st.com +46 46 706 500 show locationCanton

United States 40.786657-81.4222323 HT-AST-Canton@aalberts-st.us +1 800-648-1687 show locationLansing - bassett av

United States 42.752872-84.5756899 HT-AST-Lansing-Bassett@aalberts-st.us +1 800-648-1687 show locationUnsere Verfahren

Wir bieten weltweit alle Arten von Wärmebehandlungsprozessen an. Unsere Anlagen sind logistisch eng miteinander verknüpft, so dass Ihnen alle Verfahren zur Verfügung stehen. Erfahren Sie mehr zu unseren Wärmebehandlungsverfahren.

Heiß-Isostatisches Pressen (HIP) dient der Beseitigung von Porosität. Sie benötigen bei Lötverbindungen eine hohe mechanische Haltbarkeit und Unempfindlichkeit bei hohen Temperaturen? Wir bei Aalberts surface technologies bieten die Lösung durch Hartlöten (brazing).

Polymerbeschichtungen können auf viele Grundmaterialien aufgebracht werden und bieten lang anhaltenden Schutz. Sie sind mechanisch besonders gut mit dem Untergrund verankert und bieten verbesserte Gleiteigenschaften und/oder hohe Verschleißfestigkeit.

Mit 40 Jahren Erfahrung in der kontinuierlichen Veredelung von reel to reel können Sie sich auf Aalberts surface technologies verlassen, um innovative Lösungen zu finden. Unser Service umfasst Trommelgalvanik, kontinuierliche selektive Galvanik und Gestellgalvanik.

Fast alle metallischen Grundwerkstoffe können mit unseren selbstentwickelten und patentierten Verfahren durch Oberflächenbeschichtungen in ihren Eigenschaften optimiert werden, egal ob sie besonders hart, glatt, verschleißfest oder korrosionsbeständig sein sollen.

Discover our services

We offer all types of heat treatment processes. Our facilities are closely interlinked in terms of logistics, which means that all processes are available to you. For a complete list and description of heat treatment technologies please select the button.

Hot isostatic pressing (HIP) is used to eliminate porosity. Do you need high mechanical durability and insensitivity to high temperatures for solder joints? We at Aalberts surface technologies offer the solution through brazing.

Polymer coatings can be applied to a wide variety of base materials and offer long-lasting protection. They are particularly well anchored mechanically to the substrate. Additional enhancement layers allow non-stick coatings to be combined with improved sliding properties and/or high wear resistance.

With 40 years of experience in continuous reel to reel finishing, you can depend on Aalberts surface technologies to find innovative solutions that other companies might say are impossible. Our service includes barrel plating, continuous selective plating and rack plating.

Almost all metallic base materials can have their properties optimised by surface coatings using our proprietary and patented processes, regardless of whether they should be particularly hard, smooth, wear-resistant or corrosion-resistant.

The Aalberts websites use cookies (read more) to analyse website usage and improve usability. We also use third party tracking-cookies to measure user preferences, enable content sharing on social media and interest-based advertising. If you hit 'accept' you allow to us to place the different types of cookies.

privacy overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-functional | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |