surface treatment

Aalberts surface technologies Berlin

about this location

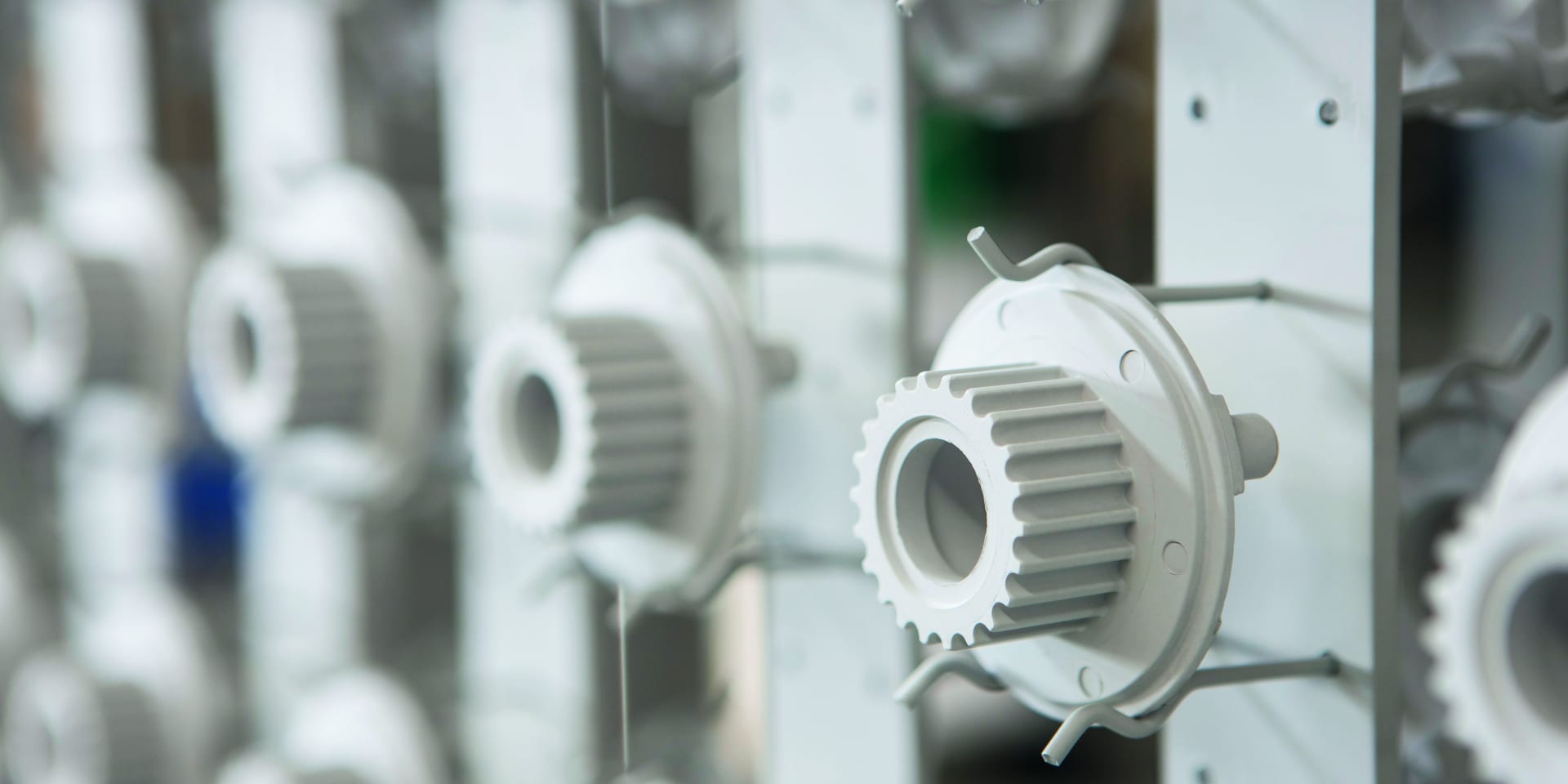

Our consistently high quality wins the trust of our customers. Aalberts Surface Technologies GmbH (the German equivalent of “Ltd “) is your partner in Berlin when it comes to surface coating, corrosion and wear protection for your technical components. And there are many more surface properties that our surface treatment company is able to produce!

welcome to Berlin

“Stern-Radio”, under this name radio sets were produced in the GDR. The main plant in Berlin-Marzahn also included the electroplating manufacturing plant in the present-day Springpfuhl industrial estate, which was acquired by the AHC almost two years after the fall of the Berlin Wall in 1991. Since then, a consistent path of modernization and automation has been taken, which continues to this day. Since 2019 we have been offering surface coating technology in Berlin as part of the Aalberts Group, including:

- color anodizing of metals (aluminum)

- hard coating,

- electroless nickel plating,

- plasma chemical coating.

Except for one manual electroplating system, all surface technology coating systems in Berlin today are fully automatic, including the documentation of all process parameters.

The Aalberts surface technologies plant in Berlin offers surface technology produced in a 3-shift operation with around 80 employees and regularly trains surface coaters.

our surface treatment services in Berlin

process overview

| process | max. size in mm | max. weight in kg |

| Color anodizing on titanium | 300x300x300 | 10 |

| Anodizing black | 1200x800x300 | 300 |

| Anodizing colorless | 1200x800x300 | 300 |

| HART-COAT® black | 1200x800x300 | 300 |

| HART-COAT® colorless | 1200x800x300 | 300 |

| DURNI-COAT® DNC 520-AL | 900x800x300 | 300 |

| DURNI-COAT® DNC 471 lead-free | 1200x1050x450 | 300 |

| DURNI-COAT® DNC 520 | 2200x1100x450 | 300 |

| DURNI-COAT® DNC 571 steel | 1200x1050x450 | 300 |

| KEPLA-COAT® black | 2000x1100x450 | 300 |

| KEPLA-COAT® white | 2000x1100x450 | 300 |

| MAGOXID-COAT® black | 500x500x400 | 10 |

| MAGOXID-COAT® white | 2200x1100x450 | 300 |

| META-COAT® / HD | 1200x800x300 | 300 |

| Tin plating matt | 900x800x300 | 300 |

hard anodizing solution in Berlin with HART-COAT®

- HC for wrought aluminum alloys and for sand and gravity die casting

- HC-CU for aluminum alloys with high copper content

- HC-GD for aluminum die casting alloys

Through use of the HART-COAT® process in Berlin, we mainly anodize components from these customer fields: Automotive engineering, office technology, data technology, power engineering, household appliance industry, mechanical engineering, medical equipment construction, measurement technology, pharmaceutical industry, defense industry.

Our HART-COAT® process follows the standards listed here (extract):

- MIL-A-8625 (US Defense)

- DIN 17611

- VW TL 212

(Process-related restrictions may result in deviation from the norm)

electroless nickel plating in Berlin with DURNI-COAT®

- Corrosion and wear resistant

- DNC 471/571 for steel

- DNC-Al 520 for aluminum and aluminum alloys

The customer industries for DURNI-COAT® -refined components include, among others: Valve construction, automotive engineering, mining, office technology, chemical industry, data technology, railway technology, electrical engineering, energy technology, aircraft construction, household appliance industry, hydraulic industry, communication technology, mechanical engineering, medical equipment construction, measuring technology, pharmaceutical industry, pneumatics industry.

Our DURNI-COAT® process follows the standards listed here (extract):

- DIN EN ISO 4527

(Process-related restrictions may result in deviation from the norm)

technical anodizing solution in Berlin

Technical anodizing is also used as a corrosion undercoating before painting components that are used near the sea.

Our technical anodizing process follows the standards listed here (extract):- MIL-A-8625 (US Defense)

- DIN 17611

- DIN EN 2284

- VW TL 212

plasma chemical coating solution in Berlin with KEPLA-COAT®

KEPLA-COAT® is a plasma chemical coating for the refinement of aluminum and titanium alloys.

The KEPLA-COAT® coating protects aluminum and titanium from wear and corrosion and, due to its surface structure, enables the absorption of lubricants as well as subsequent workpiece treatments such as varnishing or impregnation.

In addition to excellent wear protection, KEPLA-COAT® offers absolute contour accuracy, dimensional accuracy and hardness. KEPLA-COAT®-coated substrates have a considerably higher fatigue strength than substrates with comparable layers.

The layers resist aggressive gases such as chlorine and boron trichloride. In addition, KEPLA-COAT® guarantees very good sliding properties, especially in combination with PTFE or other dry lubricants.

On our Berlin manufacturing site, we offer plasma chemical coating services using KEPLA-COAT® to customers from various industries, including among others: Automotive engineering, data processing, electronics, power engineering, communication technology, aerospace industry, optical industry, mechanical engineering, medical device construction, vacuum technology.

plasma chemical coating solution in Berlin with MAGOXID-COAT®

MAGOXID-COAT® is a plasma chemical coating for the refinement of magnesium alloys.

The MAGOXID-COAT® coating composite protects magnesium alloys against wear and corrosion and, due to its surface structure, enables the absorption of lubricants as well as subsequent workpiece treatments such as painting or impregnation.

The plasma chemical process leads to crystalline oxide ceramic layers which, in addition to high wear and corrosion protection, also meet other requirements such as hardness, contour accuracy, flexural fatigue strength, dimensional stability or temperature resistance.

We offer plasma chemical coating services in Berlin using MAGOXID-COAT® to customers from various industries, including: Automotive engineering, fittings manufacturing, office technology, data processing, power engineering, household appliance industry, communication technology, aerospace industry, optical industry.

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

industries we serve

contact & directions

Aalberts Surface Technologies GmbH