providing the chemical industry with ground-breaking surface technologies

invulnerable surfaces for clean processes

The chemical industry requires solutions which are both easy to clean and highly resistant to chemicals and high temperatures. Our solution optimisations ensure that even the most challenging production environments are covered. For over 60 years, we have been providing the chemical industry with high-quality, innovative solutions.

benefits of chemical industry

solving the industry’s key challenges

The chemical industry faces a number of key challenges when carrying out processes within their production plants. These are:

- Wear and tear

- Corrosion

- Static charge

- Contamination

- Aggressive chemicals

- High temperatures

Parts exposed to chemical processes need to be 100% free from pores and resistant to a wide variety of chemicals. They need to be resistant to chemicals, easy to clean, and have excellent non-stick properties.

To be able to master these challenges, surfaces need to be both very resistant and of high quality. And these properties need to positively impact production results and be economically efficient.

Today, more than 850 customers from all over the world rely on our high-performance surface finishes. As experts in the field of innovative high-quality solutions, surface technology in the chemicals industry is one of our core competencies—and we strive to undertake any challenge, no matter what it is.

Special fluoropolymer and polymer coatings have become well established as surface coatings in the chemical industry. These hydrophobic plastic coatings are characterised by outstanding non-stick and traction properties, longevity and superior corrosion protection.

With a thickness ranging from a few µm to several hundred µm, the layers offer long-term protection against aggressive bases and acids with a pH value of up to 12. They are able to resist temperatures up to 250°C, and they become firmly anchored in the substrate and are suitable for a wide variety of (non-)ferrous materials:

- Steel

- Stainless steel

- Aluminium

- Plastics

- Ceramics

- Copper

We can tailor the surface structure and roughness (from approx. 1.5 µm) to your individual needs. And problems arising from processing substances that are extremely difficult to remove can be reduced: containers can be cleaned in less time and without leaving any residues, less release and cleaning agents are required, and maintenance is reduced.

customised chemical surface technologies

We provide products that are perfectly suited for a wide variety of applications. With nineteen partially patented special surface finishes, our surface technologies are represented in many branches of the chemical industry. Not only do our development engineers focus on the expansion of current processes, they continuously work on developing innovative new ideas.

Interested in real-world cases? Read on to discover the benefits of our chemical surface technologies.

Biodiesel is an aggressive fuel, which damages the tanks it is stored in. But replacing or repairing biodiesel tanks is both time-consuming and expensive, which is why the inner tank walls have to be resistant to chemicals and corrosion. Thick-layered polymer and fluoropolymer coatings (MagnaCoat®) protect the surfaces against corrosion and the damaging effects of biodiesel. The result is a reduction in paintwork, repairs and premature new acquisitions.

Manufacturing paints and varnishes involves mixing containers and agitators. Because the blending process occurs at high speeds, solvent vapours can escape. And due to the static charge of the agitator, there is a risk of reaction with these solvent vapours. Additionally, the containers and agitators need to be cleaned, which is time consuming, before each new blending process.

By applying a ChemCoat® version specifically developed for this type of application, it is possible to keep paint residues from sticking to mixing containers and agitators. ChemCoat® is a series consisting of high-quality non-stick and anti-friction coatings. We use carbon fibres to ensure that the coating is conductive. Thus, it is possible to reduce cleaning times and avoid static charges.

The mining of brown coal involves transporting wet coal for the purposes of further processing. This is done by conveyor systems, which contain vertically arranged conveyor plates. But due to the wet coal’s weight, these plates come under a great deal of strain and are subject to heavy wear. And the plates are frequently clogged with coal residue, which means they need to be cleaned frequently.

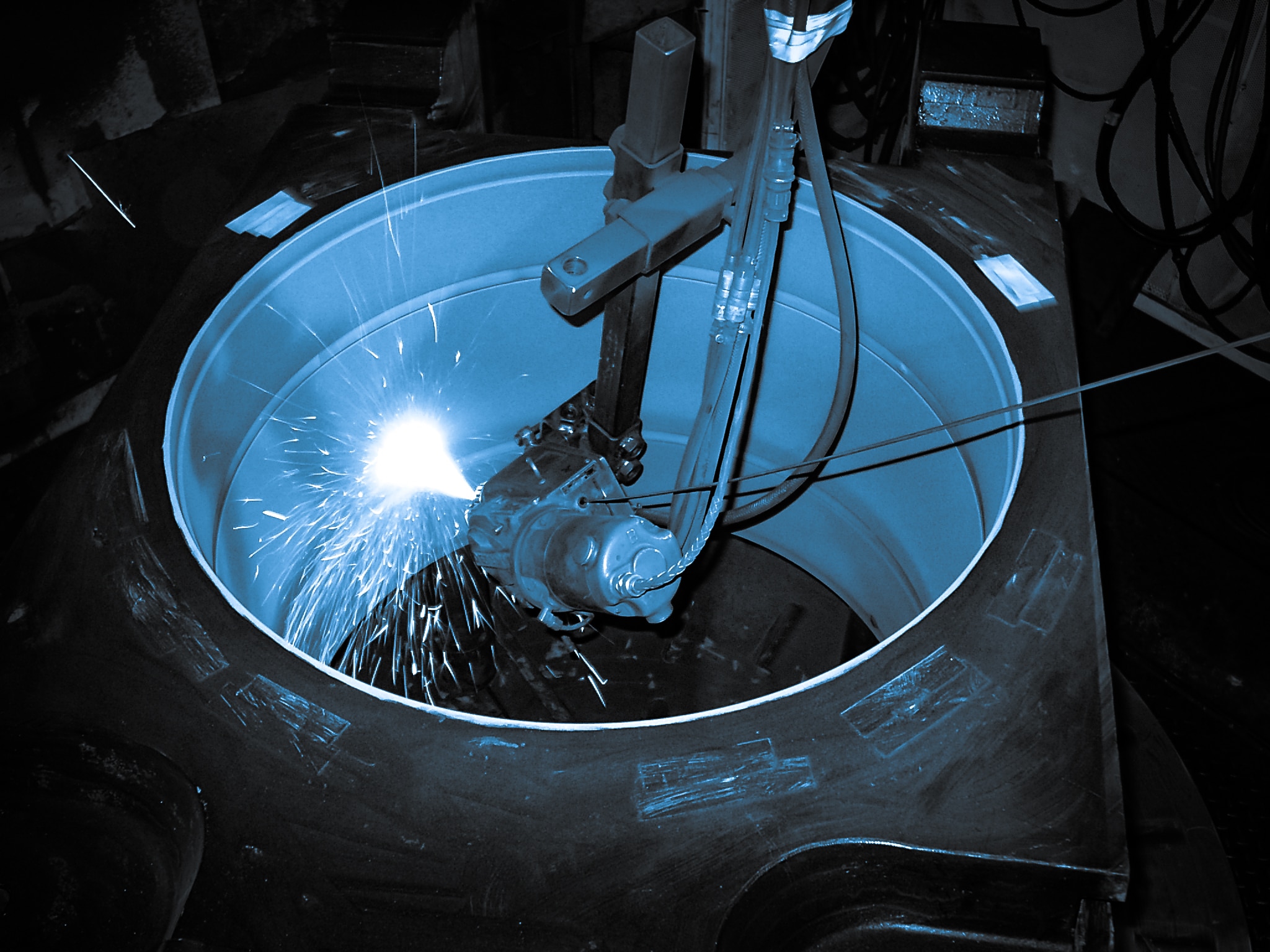

When coating their conveyor plates with PlasmaCoat®, companies active in this field can benefit from good wear protection and non-stick properties. Transport problems caused by wet lignite no longer occur, while the plates’ replacement intervals become longer. What’s more, PlasmaCoat® significantly reduces cleaning and maintenance costs. This coating process merges the extreme surface hardness and extraordinary wear protection of thermally sprayed metal or ceramic coatings with the non-stick and anti-friction properties of polymers and fluoropolymers.

relevant process locations

get in touch

Select your preferred process location or contact us directly.